Products

- APPLIANCE

- FURNITURE

- AUTOMOBILE PARTS

- IT

- ARCHITECTURE

- AGRICULTURE, FORESTRY AND SPECIAL

- HEAVY DUTY ANTICORROSION

- STEEL COILS

- FUNCTIONAL

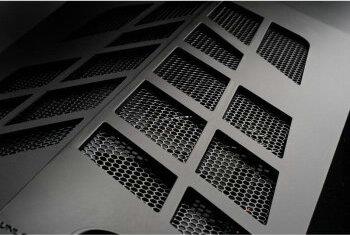

IT powder coatings

Product series

---standard curing and low temperature curing products

---can be made of a variety of gloss and color products: specific gloss color to the user specified as the standard

---can be made into a variety of special surface appearance products: such as sand lines, continuous lines, wrinkles, metal effects, etc.

Product characteristics

---super decorative properties

---excellent chemical properties

---excellent physical properties

---stable spraying construction

Product Detail

---suitable for all kinds of electric control cabinet, network cabinet, power controller

---high voltage electrostatic spraying or friction - coated products

---coating thickness: in the use of 60-120 microns, the proposed film degree of 80-100 microns

---average coverage: 6-9 square meters / kg, film thickness of 80-100 microns (to 100% usage)

---specific gravity: 1.5-1.7g/cm3 (due to different formulations and colors)

---particle size distribution: the use of different types, the standard type for the average particle size of 35-40 microns, less than 100 micron powder <10%, greater than 100 micron powder <0.5%

Film performance --- all tests were performed using 0.8mm cold rolled steel plate in thick oil and rust, the film thickness of 50-120 microns

Product packaging

---carton packing, lined with single layer thick film polyvinyl chloride plastic bag, net weight 20kg or 25kg per carton

Storage condition

---the product should be stored in a dry, ventilated room at 35 degrees C, while avoiding direct sunlight. As in the air conditioning room storage, before use to powder at room temperature or with the same spraying equipment (temperature) storage, avoid damp. Under the above conditions, the powder can be stored stably for 12 months

Health and safety

---product raw material does not contain toxic substances, are in line with RoHS and reach, the baking free of toxic gases produced, but it should be avoided in the use of inhalation of dust in the process, the operator should wear a dust mask, and minimize the long-term exposure of skin and powder coating, attached to the skin of paint, can be washed with soap